The spray drying machine is specialised equipment that uses spray drying to dry a liquid or solution to generate dry powder rapidly. Spray drying is the most cost-effective method of producing dried powders. Powder spray drying machines play a vital role in the industry for powder drying operations. A spray drying machine can swiftly dry materials with excellent quality and minimal water activity for easy shipment. Laboratory spray dryer manufacturers make machines in the chemical industry, plastic resins, the food business, ceramics, and other fields.

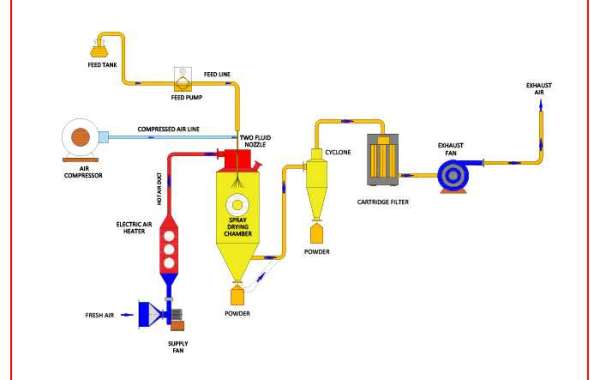

The lab spray dryer machine may have different designs depending on the materials or product requirements. Still, the actual core units that make up the spray drying system remain the same, requiring numerous significant systems.

Understand the essential parts of a lab spray dryer system and their separate roles:

Top-grade products from Laboratory spray dryer manufacturers

Feeding system

The feeding system smoothly distributes the material liquid to the atomiser to ensure proper functioning. The feeding process varies depending on the atomiser employed and the type of the substance. Screw pumps, measuring pumps, diaphragm pumps, and other feed pumps are commonly utilised. Compressed air is necessary for airflow atomisers to satisfy the energy requirements for material atomisation. Therefore, the outside the material pump, there is a requirement for the air compressor.

Heating system

One of the laboratory spray dryer components is the heating system. It generates adequate heat for drying and delivers it into the dryer via air. Certainly, the nature of the substance and the needs of the product are still the most important factors to consider when choosing a heating system. The two main types of heating equipment are direct heat delivery and indirect heat exchange. Additionally, the heating system also includes the fan.

Atomiser mechanism

The entire spray drying system revolves around atomization technology. Drying professionals have spent the most time studying the atomizer, from theory to structure. The three fundamental atomiser types are:

Centrifugal- The machine's high-speed rotation generates significant atomisation power. The principal atomization power comes from the feed pump's high pressure, which is transferable to kinetic energy. As a result, the main atomisation power comes from high-speed airflow kinetic energy.

Industries use different types of atomisers based on the intended product qualities (form, structure, and size) and the nature of the feed solution. The most frequent devices utilised in the bulk of atomisation procedures is mentioned in the following sections.

Rotate Atomizers

The feedstock solution is driven to the rotary atomiser's horizontal wheel or disc centre. The centrifugal force speeds the feed solution to the perimeter, generating a droplet spray. Grooves in the atomiser disc are frequent because these designs maximise control over the solution dispersion induced by rotating at high speeds.

Hydraulic nozzles Atomizers

The hydraulic nozzles, also known as one-fluid nozzles, work by forcing a feed solution through a conduit with a gradually decreasing diameter. Furthermore, the fluid is atomised as it emerges through a small nozzle orifice (typically 0.4 to 4 mm in diameter) at a high velocity with a concomitant pressure loss, causing it to disintegrate into droplets.

Pneumatic nozzles Atomizers

Multi-fluid nozzles are another name for pneumatic nozzles. The most typical form of these devices is a two-fluid nozzle atomiser. Therefore, it takes in both the feedstock solution and the compressed gaseous atomising medium. Depending on the configuration, the gas separates from the feedstock solution and meets it inside or outside the nozzle. According to Weber, atomisation occurs when high gas velocity induces high frictional forces over the liquid surface. The feedstock solution forms a cloud of droplets. Additionally, the speed and density of the gas controls the atomisation process, its direction, and the liquid/gas ratio.

Drying system

Various dryers together form the drying system. In deed, the atomiser, which is also the major component of the spray drying design, influences the shape of the dryer to some extent.

Separating gas and solids System

Dry and wet separation are the two primary components of the gas-solid separation system. The droplets lose most of their water during drying, resulting in a powder or granular product separated from the gas at the drying tower's bottom and expelled from the dryer. On the other hand, others follow the tail gas into the gas-solid separation system for further separation.

With this, we hope you will better understand spray dryer components. Hence, don't hesitate to call laboratory spray dryer suppliers when you are looking for a reliable spray dryers.