Instrument Certification is one of the most important steps for ensuring instrument accuracy. Calibration is the process of setting up an instrument such that it can produce a result for a sample that is within a reasonable range. Instrumentation design revolves around removing or eliminating factors that lead to faulty measurements.

Although the specific approach varies by-product like Thermometer Calibration, the calibration process generally include testing samples of one or more known values with the instrument.

Frequently Asked Questions Regarding Instrument Calibration

What Is Instrument Calibration?

One of the most important steps for maintaining instrument accuracy in major industries is instrument calibration. Calibration is the process of setting up an instrument such that it can produce a result for a sample that is within a reasonable range. Instrumentation design revolves around removing or eliminating factors that lead to faulty measurements.

Although the specific approach varies by-product, the calibration process generally includes testing samples of one or more known values called "calibrators" with the instrument. The results are utilized to build a link between the instrument's measuring approach and the known values.

What Is The Significance of Calibration?

All measurement instruments lose precision over time which usually is the result of normal wear and tears. Electric or mechanical shock, as well as a hazardous manufacturing environment, can induce variations in precision. The bottom line is that calibrating enhances the measurement device's accuracy. Product quality is improved by accurate measuring devices.

How Can You Know If Your Instrument is Calibrated?

Equipment calibrated at calibration laboratories/centres is always accompanied by a calibration certificate. Each calibrated item comes with a sticker that includes information like the serial number and calibration data. When possible, the sticker is applied to the equipment.

Are There Any Deadlines for My Certificates?

Many factors influence the actual due date, and the calibration laboratory cannot examine the bulk of them. When an item should be recalled for calibration, factors like drift, manufacturer's recommendations, calibration history, and end usage all play a role. In these instances, the client is the final authority. If a due date appears on your certificates or stickers, it is simply for the user's convenience and is not indicative of a specific date when the instrument has to be calibrated.

What Is Temperature Calibration?

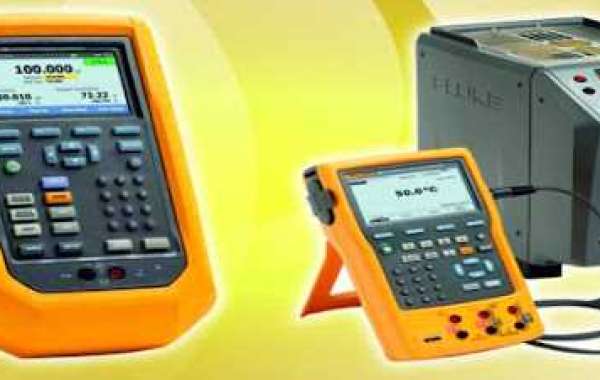

It is a device that can simulate temperature sensors or temperature sources as a point of reference with a known level of uncertainty or accuracy for data. Further, it is compared to temperature readings from a temperature measuring device, such as a thermometer or transmitter to suspect a level of accuracy.

Temperature calibrators are available in a range of shapes and sizes. To various people, a temperature calibrator can signify different things. The way a person defines a temperature calibrator is frequently influenced by their application. If you are among some people who think of Thermometer Calibration as a handheld gadget that electrically simulates temperature sensors as if they were at the desired temperature, then you might be partially right.