What are the Prerequisites That You Would Need to Meet in Order to Be Able to Take Advantage of the Benefits That a Vertical Carousel Offers?

The short answer is that you wouldn't want the benefits unless you were interested in lowering your overhead costs, improving the efficiency of your operations, enhancing the way you manage your inventory, and providing a safer working environment for your employees. On the other hand, given your exceptional leadership within the company, you really ought to be eligible for any and all of those perks. A vertical storage carousel affords its users a number of advantages, some of which are detailed in the following paragraphs:

1. Making the most of the space available in the overhead area in order to reduce expenses in the overhead category

Because Smart tower storage makes use of the space that is available vertically, a vertical carousel can cut your overall storage footprint by as much as 75 percent. In contrast, the vast majority of automated storage systems make extensive use of horizontal space and this stands in stark contrast to that fact. If you want to save money on real estate, you should reclaim any unused overhead space in your building and reduce the size of any storage areas you have. This will allow you to make more room for other uses.

2. Boosting the output of operations while simultaneously improving productivity in order to boost profits

On a vertical carousel, all of the necessary supplies, pieces of equipment, and commodities are always within an easy reachable distance. To retrieve rolled or boxed materials, or products that have been stored, there won't be any more time-consuming walks across the warehouse anymore. Because the manufacturing process as well as the delivery of goods to retail locations are both becoming more efficient, this translates to the fact that additional tasks can be completed in the same amount of time.

3. Strengthening of safety and security measures with the goal of lowering insurance premiums

Your already established safety procedures will be significantly improved by the addition of vertical carousels. They bring everything that needs to be worked on directly to the workers, so there are never any accidents involving lifting or crushing. Accidents that take place while you're on the job won't have any impact on the cost of your premiums. The presence of security mechanisms allows for the prevention of a variety of undesirable occurrences, including theft, poor management, and picking errors. Your insurance premiums and replacement expenses are brought under control.

4. Tailoring the available storage options to the unique requirements of the expanding business

There are a lot of storage solutions that are made to be universally applicable, but that does not necessarily mean that they will be suitable for you. The user's specific requirements can be accommodated through the implementation of a number of adjustments and modifications to the vertical storage system. If the workflow of your company is not forced to change in response to the storage systems that you use, then your company's level of productivity will not take a hit as a result. The retail sector, the healthcare industry, the research sector, and the manufacturing sector can all benefit from the utilization of carousels as an effective tool in their respective industries.

When taken into account as a whole, each of these advantages will have a constructive impact on the financial status of your organization. Why, then, wouldn't you want to make use of the advantages that vertical storage can give you?

Vertical Carousels Australia supplies a wide variety of industrial warehouses and other facilities with automated storage systems, vertical carousels, vertical lift modules, and a great deal more. These products are of the highest possible quality. Vertical Carousels Australia's headquarters can be found in that country. These kinds of automated stitching can be obtained from respectable manufacturers like Modula, Kardex, Remster, and so on, and they can be bought at prices that are not unreasonably high. Even the option to purchase vertical carousels that were previously owned is made available by Vertical Carousels Australia. Following the completion of a detailed performance analysis, each of the previously owned machines is then given a warranty that is good for a period of three months after it has been purchased. If you have any further inquiries, please do not hesitate to contact VCA so that we may provide you with a consultation that is both straightforward and educational.

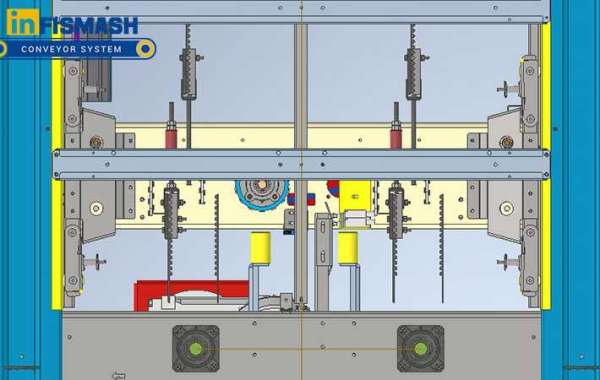

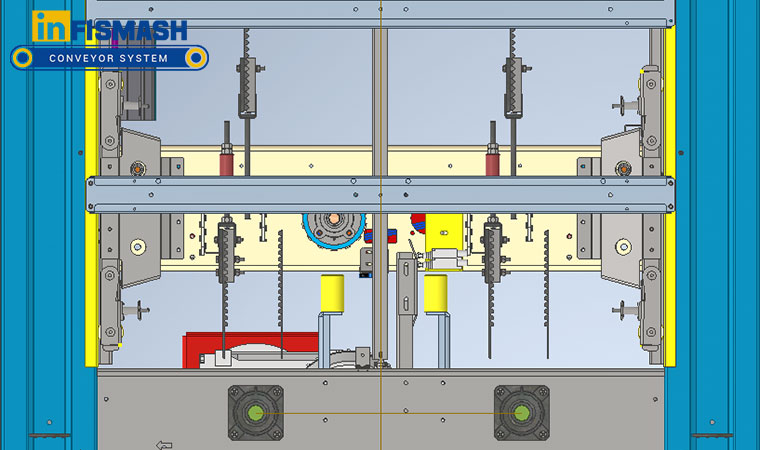

Why Do Conveyor Belt Systems Modules Present Such a Massive Opportunity for Advantage for Manufacturers in the Present Market?

A common method of storing items that can be found in a wide variety of warehouse environments as well as other kinds of businesses.

A vertical lift module, or VLM for short, is an enclosed storage system that is constructed of vertical stacks of trays connected by a centralized elevator that runs vertically between them. Another name for this type of storage system is a vertical lift module. It is possible to achieve a true goods-to-person pick solution as a result of the elevator's responsiveness to commands and its ability to retrieve and automatically transport trays to the operators. This is possible because the elevator is capable of both of these things.

Vertical lift modules have become a popular option for storage in a wide variety of warehouses located in a wide variety of industries. This is due to the fact that they combine technology and design in a way that makes them a unique product. VLMs have the potential to offer a competitive advantage in the challenging manufacturing environment of today by increasing the amount of available floor space, optimizing the storage density, boosting both efficiency and productivity while simultaneously lowering labor costs. These benefits can be achieved by increasing the amount of available floor space; optimizing the storage density; and increasing the amount of available floor space.

The amount of available floor space can be increased through the use of vertical lift modules.

On the ground level of the warehouse, the vertical lift modules take up only a very small portion of the available space. They are taller than they are wide, which not only makes the most of the available space overhead but also makes significant amounts of space on the ground available that can be put to other uses. The scalability and capacity grading of VLMs are two additional methods that can be utilized to bring about an increase in storage density. As a direct result of this, the VLMs that are offered by Vertical Carousels Australia call for ninety percent less space on the floor than does traditional racking.

Vertical Lift Modules help cut down on the amount of time spent picking.

An operator controls a motorized elevator that moves between stacks of trays in a vertical lift module in order to find and retrieve specific trays. This is done in order to maximize space utilization. However, individual throughput rates can differ depending on the design of the Smart tower storage Module (VLM) and how it is put to use. Items that are kept in a Assembly Lines System Module can usually be handed over to the operator in a time period that is less than forty-five seconds. When a pod of machines is attached to a VLM, it is possible for that particular VLM to achieve throughputs of up to 500 LPH.